Why Egy Polymers?

Polymers World…..

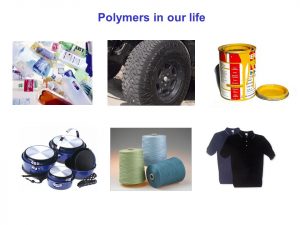

When establishing Egy Polymers strategy, our business consultant asked us “why to use the word polymers in your name. Sure, it’ll limit your business?!!” our reply was shocking for him “it’s a broad term which includes almost everything we use in our lifestyle”.

Polymers in our daily life

A polymer is a large molecule or a macromolecule formed by joining many repeated subunits. They may be naturally found in plants and animals (known as natural polymers) or may be man-made (called the synthetic polymers). To date, the importance of polymers has been much more highlighted because of their applications in different dominions of sciences, technologies and industry.

A polymer is a large molecule or a macromolecule formed by joining many repeated subunits. They may be naturally found in plants and animals (known as natural polymers) or may be man-made (called the synthetic polymers). To date, the importance of polymers has been much more highlighted because of their applications in different dominions of sciences, technologies and industry.

We will list some of the important polymers and their uses in the industries and other fields.

- polypropene finds usage in a broad range of industries such as textiles, packaging, stationery, plastics, aircraft, construction, rope, toys, etc.

- Polystyrene is one of the most common plastic, actively used in the packaging industry. Bottles, toys, containers, trays, disposable glasses and plates, tv cabinets and lids are some of the daily-used products made up of polystyrene. It is also used as an insulator.

- The most important use of polyvinyl chloride is the manufacture of sewage pipes. It is also used as an insulator in the electric cables.

- Polyvinyl chloride is used in clothing and furniture and has recently become popular for the construction of doors and windows as well. It is also used in vinyl flooring.

- Urea-formaldehyde resins are used for making adhesives, molds, laminated sheets, unbreakable containers, etc.

- Glyptal is used for making paints, coatings, and lacquers.

- Bakelite is used for making electrical switches, kitchen products, toys, jewelry, firearms, insulators, computer discs, etc.

- Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a di-isocyanate or a polymeric isocyanate. Because of a variety of di-isocyanates and a wide range of polyols can be used to produce polyurethane, a broad spectrum of materials can be produced to meet the needs of specific applications.

- Flexible Polyurethane Foam

Flexible polyurethane foam is used as cushioning for a variety of consumer and commercial products, including bedding, furniture, automotive interiors, carpet underlay and packaging.

- Rigid Polyurethane Foam

Rigid polyurethane and polyisocyanurate (polyiso) foams create one of the world’s most popular, energy-efficient and versatile insulations. These foams are effective insulation materials that can be used in roof and wall insulation, insulated windows, doors and air barrier sealants.

Coatings, Adhesives, Sealants and Elastomers (CASE)

The uses of polyurethanes in the coatings, adhesives, sealants and elastomers (CASE) market offer a broad and growing spectrum of applications and benefits. Polyurethane adhesives can provide strong bonding advantages, while polyurethane sealants provide tighter seals. Polyurethane elastomers can be molded into almost any shape, are lighter than metal, offer superior stress recovery and can be resistant to many environmental factors.

- Thermoplastic polyurethane (TPU)

Thermoplastic polyurethane (TPU) offers a myriad of physical property combinations and processing applications. It is highly elastic, flexible and resistant to abrasion, impact and weather.

- Reaction Injection Molding (RIM)

Car bumpers, electrical housing panels and computer and telecommunication equipment enclosures are some of the parts produced with polyurethanes using reaction injection molding (RIM). Automotive, construction, appliance, furniture and recreation and sporting goods are a few of the markets and applications using RIM technology.

- Binders

Polyurethane binders are used to adhere numerous types of particles and fibers to each other. Their primary areas of use are in the manufacturing of wood panels, rubber, or elastomeric flooring surfaces, printing inks and sand casting for the foundry industry.

- Waterborne Polyurethane Dispersions (PUDs)

Waterborne polyurethane dispersions (PUDs) are coatings and adhesives that use water as the primary solvent. With increasing federal regulation on the amount of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that can be emitted into the atmosphere, PUDs are being used in more industrial and commercial applications.

Leave a Reply